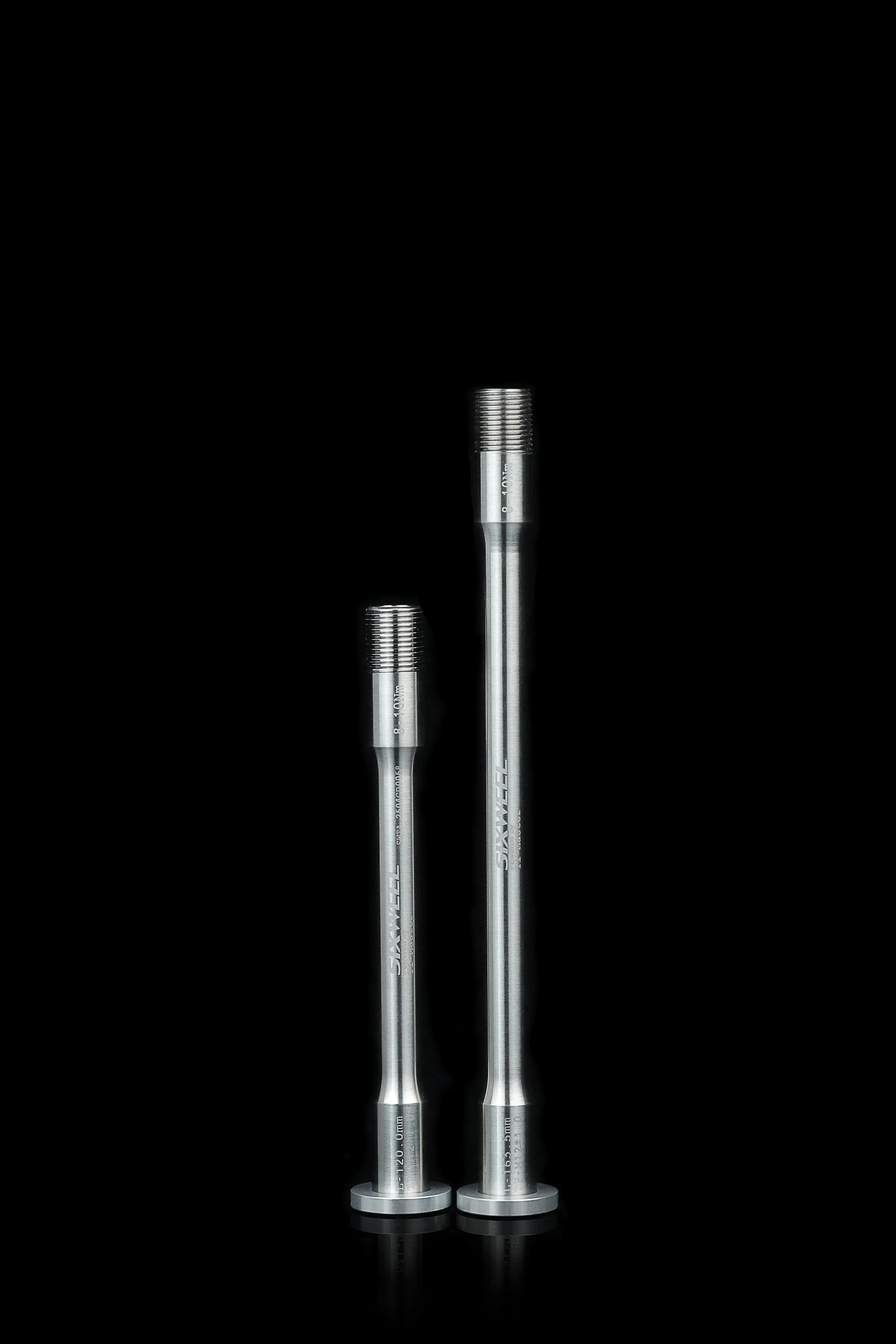

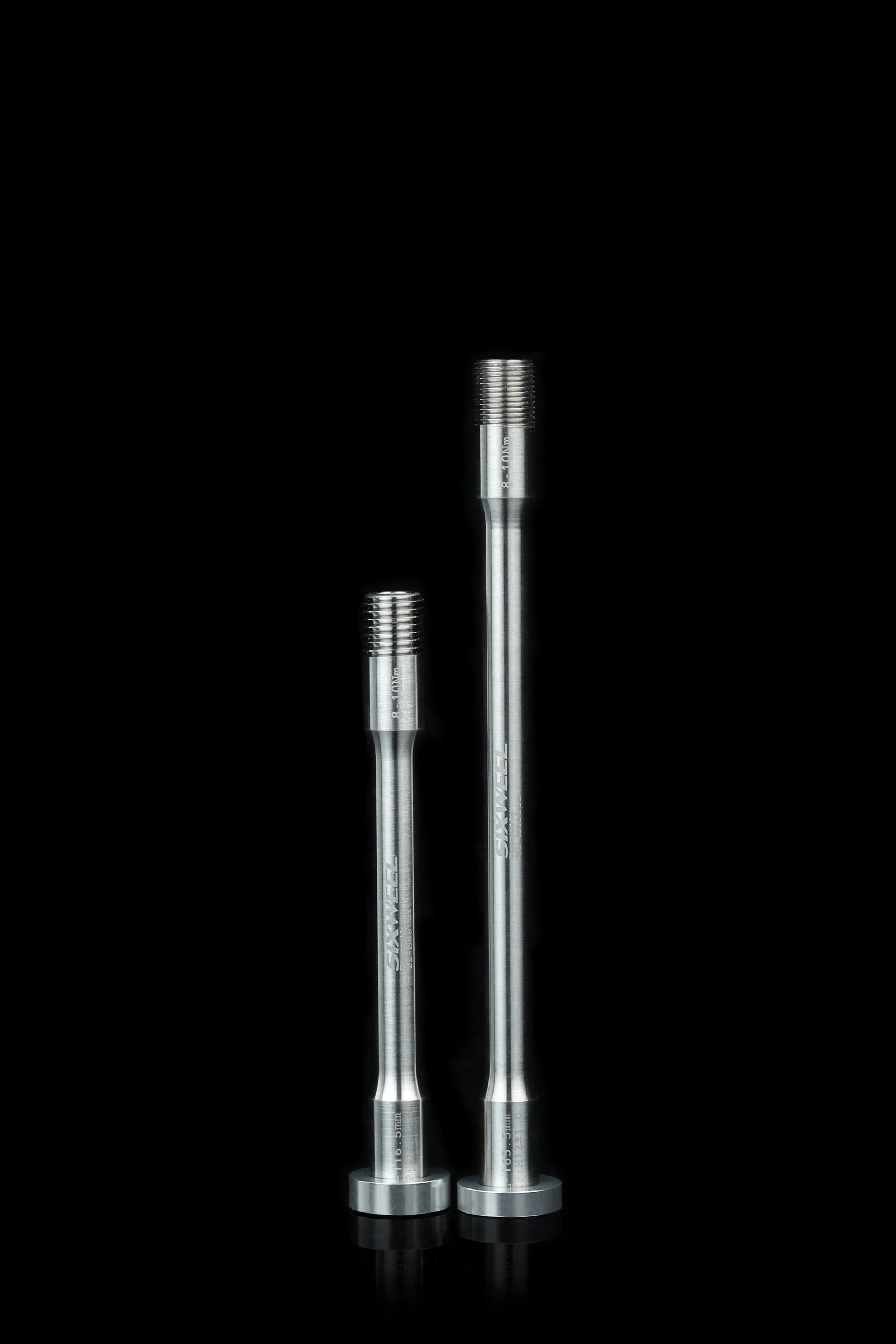

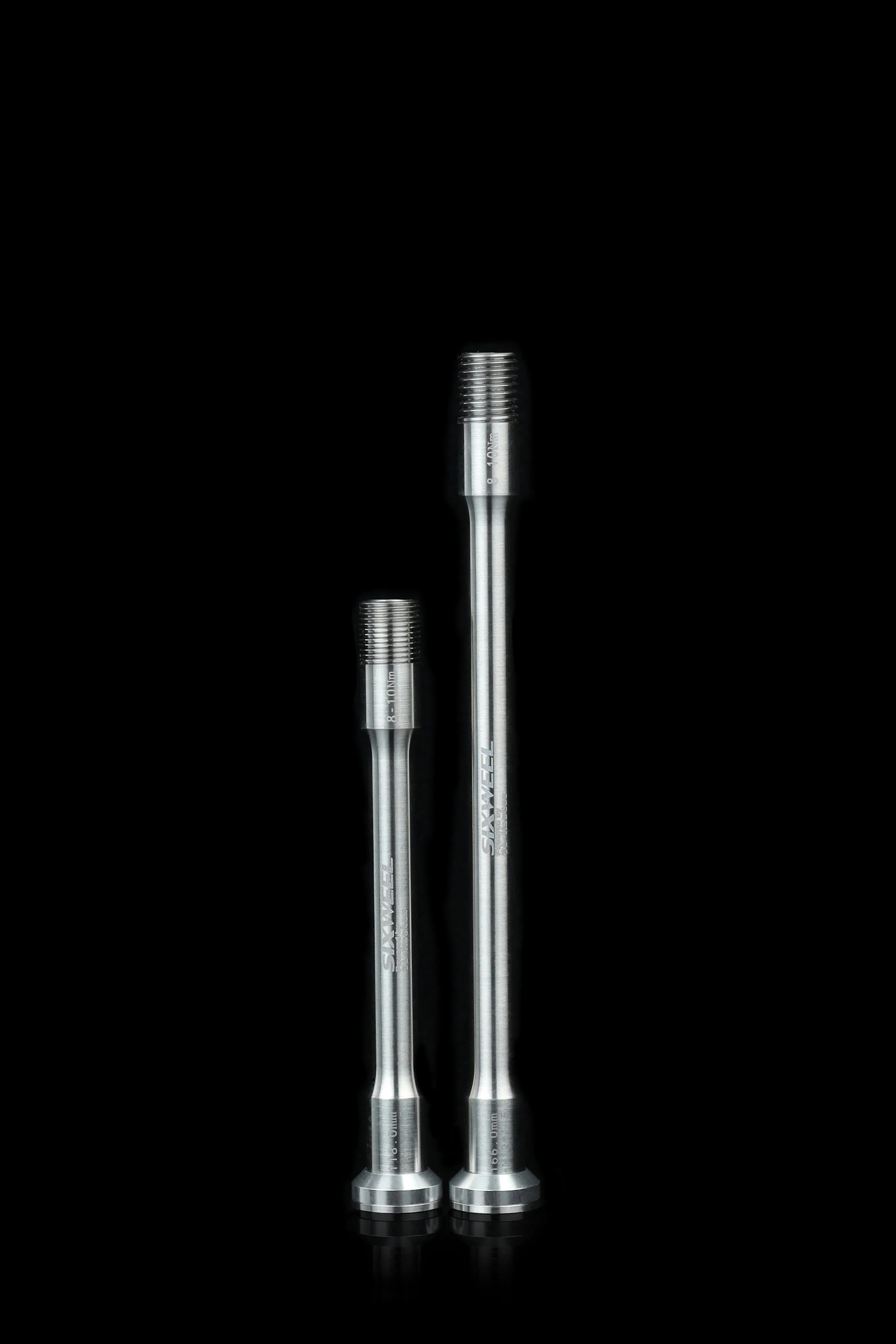

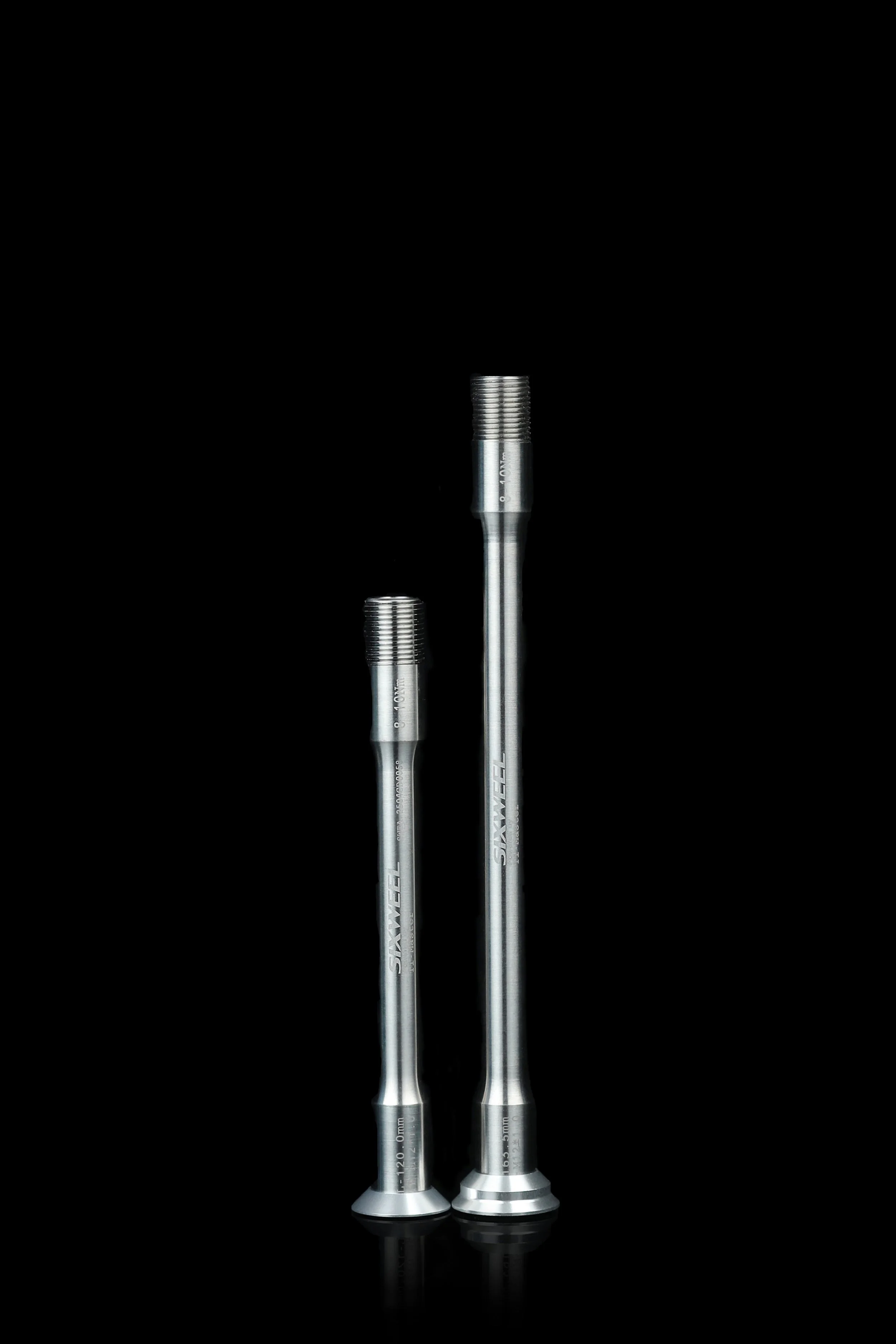

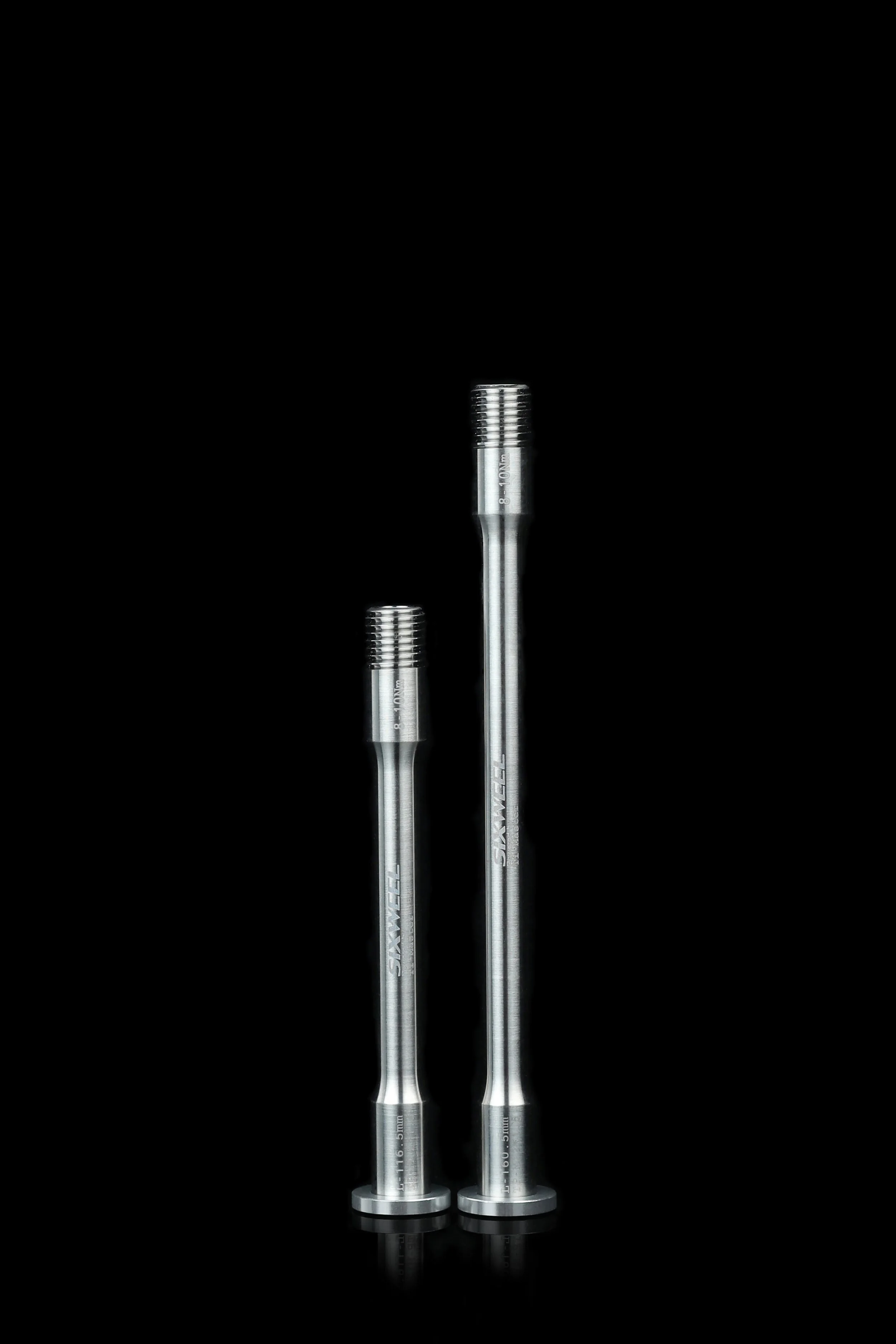

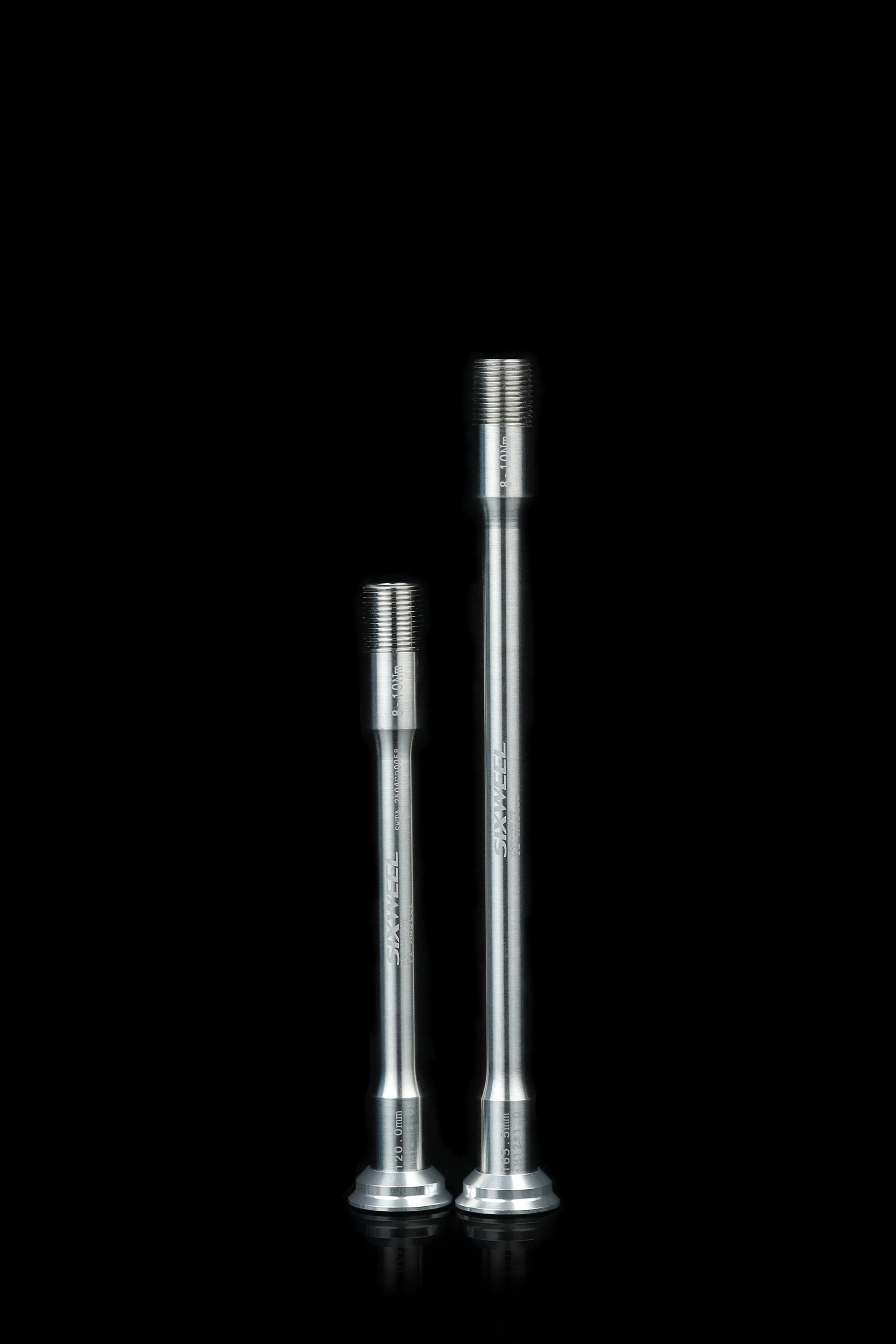

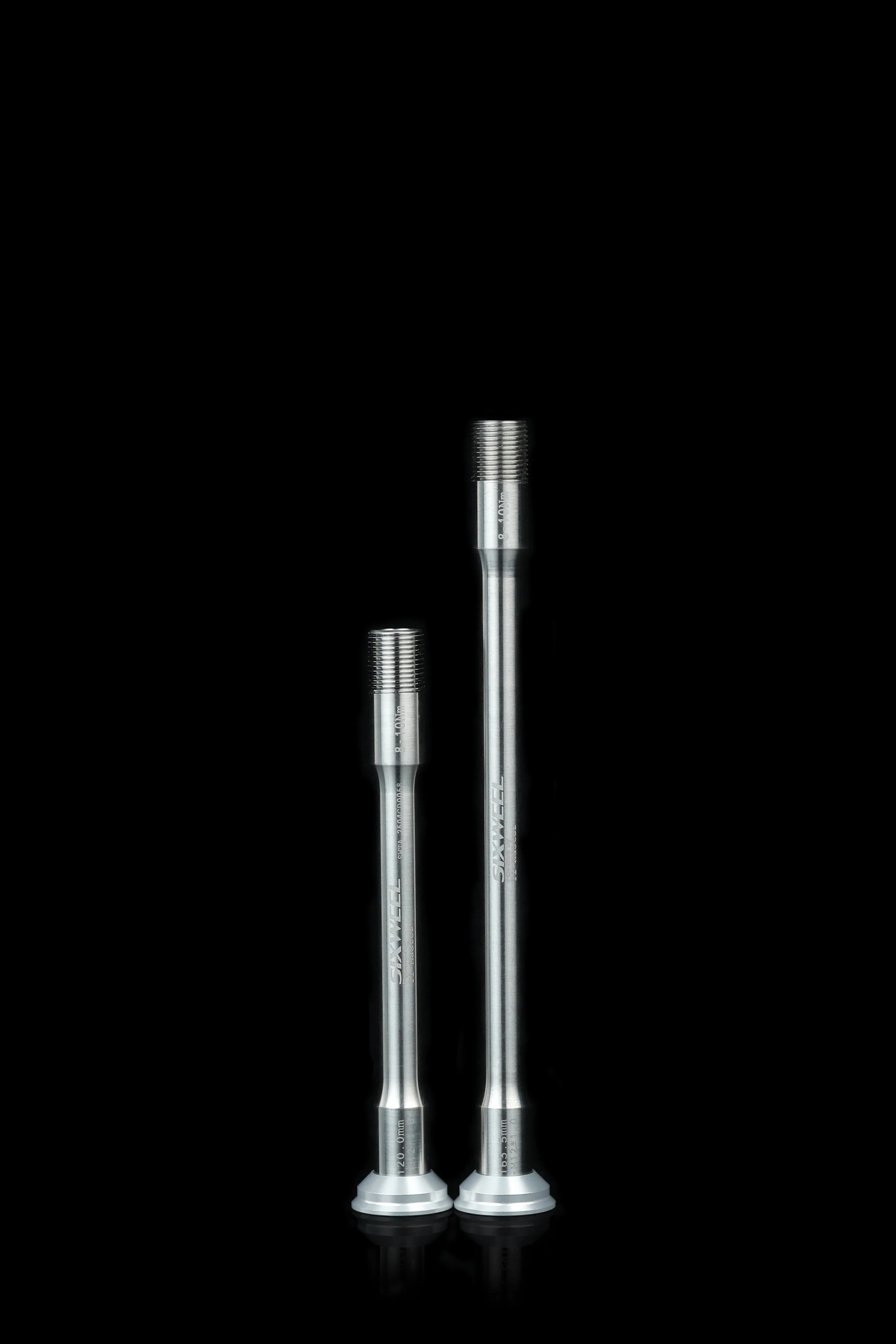

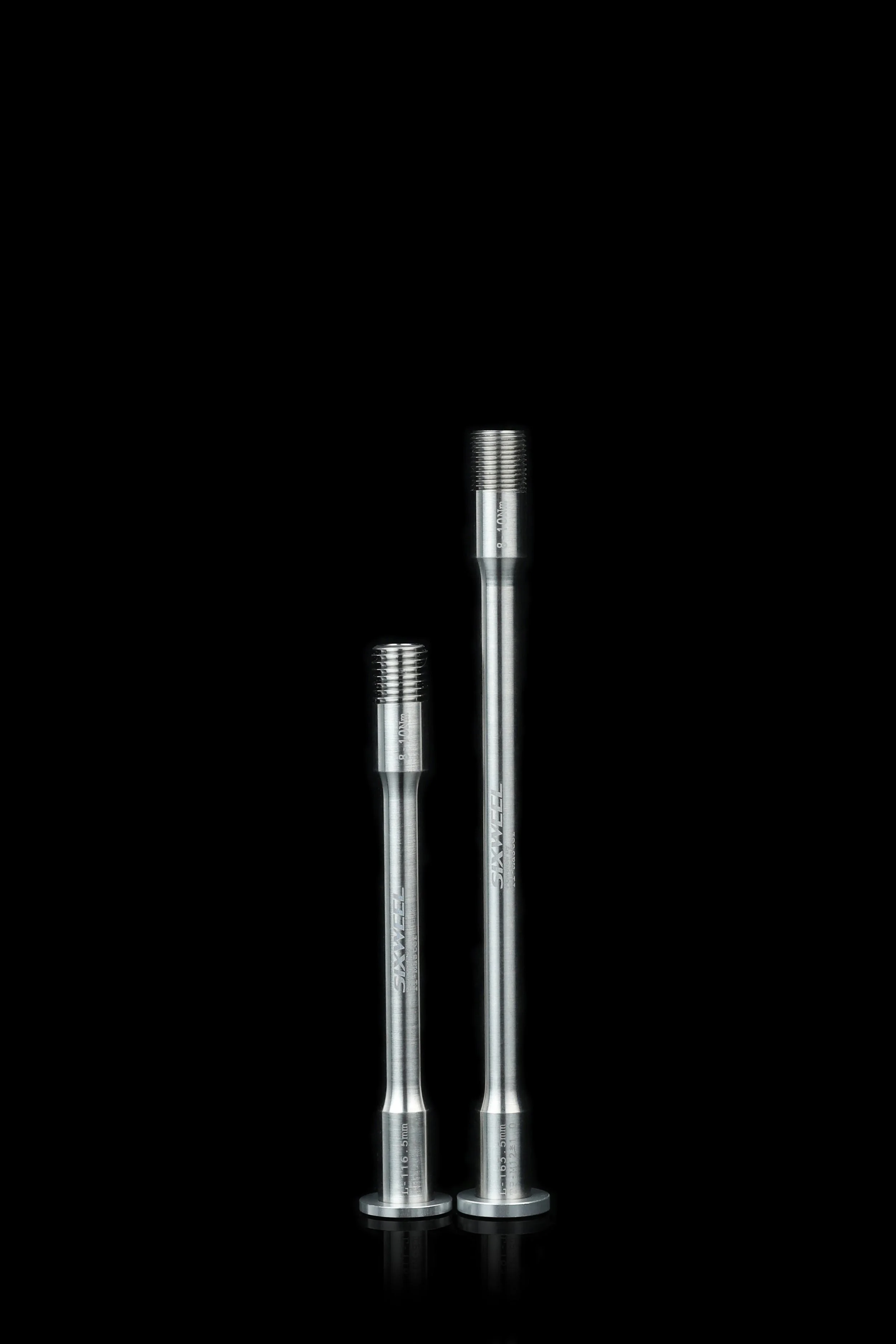

SixWeel TC4 Titanium Thru Axles – Strength, Precision, and Reliability

Designed for riders who demand uncompromising performance, the SixWeel Thru Axles are crafted from Grade 5 (TC4) titanium alloy and refined through advanced heat treatment to achieve tensile strength exceeding 1000 MPa and a surface hardness of 36 HRC.

Lightweight, Without Compromise

While many lightweight designs sacrifice safety by reducing diameter or length, SixWeel maintains critical dimensions to ensure proper load distribution and protect both washers and frame integrity.

Optimized Functionality

The 6 mm hex tool interface is reinforced with a special titanium alloy treated to 45 HRC hardness, preventing rounding or deformation even under repeated torque.

Each model includes compatible washers for perfect installation and long-term stability.

Precision Manufacturing

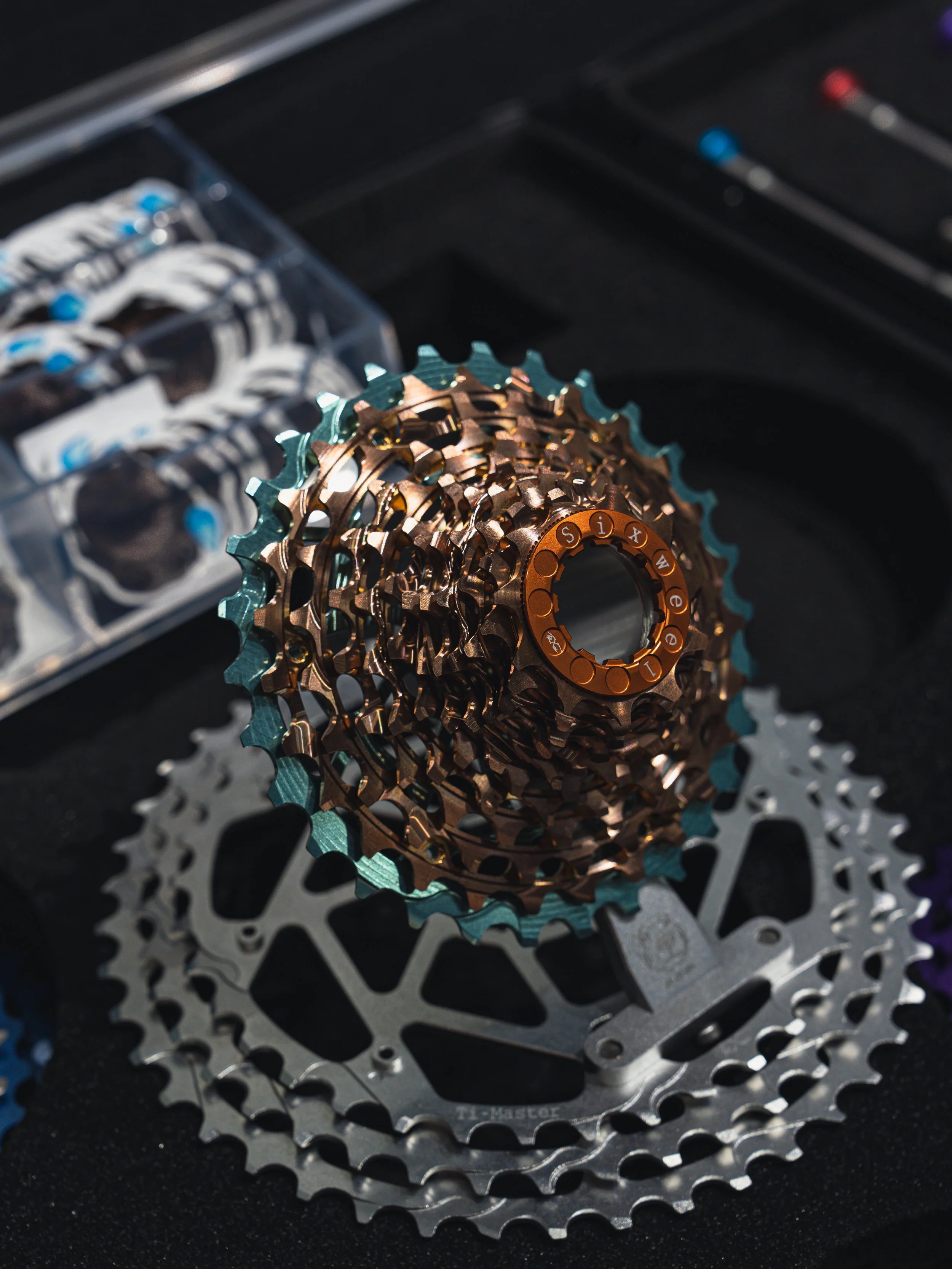

Leveraging Ti-Master technology, every axle is CNC-machined to a 0.40–0.45 mm (±0.01 mm) uniform wall thickness, guaranteeing concentricity and a cross-sectional strength of 11.2 mm². Real-world tensile testing confirms resistance beyond 1000 kgf, surpassing calculated requirements.

Rigorous Safety Testing

Torque Test:

20 Nm, 50 continuous disassembly cycles – no damage

12 Nm, 500 continuous disassembly cycles – no damage

Tension Test: Wall thickness 0.4 mm, tensile strength >1000 kgf – exceeded expectations

SixWeel TC4 Titanium Thru Axles embody the pursuit of lightness without compromise, precision without weakness, and durability without limits.