Why CNC Titanium?

Because your safety and performance deserve no compromises.

Get the highlights.

1000 MPa tensile strength, ~36 HRC hardness

Exceptional fatigue resistance — no hidden cracks

±0.01 mm CNC precision for perfect fit

100% consistency, every batch, every part

Safer than carbon fiber or 3D-printed titanium

Unmatched Strength

Our TC4 (Grade 5) titanium exceeds 1000 MPa tensile strength and ~36 HRC hardness — far stronger and safer than carbon fiber or 3d-printed titanium.

Carbon fiber thru axles can hold until a certain point, but under sudden side loads from hard cornering, pothole impacts, or sprinting torque, they might snap without warning because the material has no yield point.

3d-printed titanium, lacking post-process heat treatment, is also not as rigid and more fracture-prone than our fully heat-treated billet titanium.

The True Cost of CNC Titanium

-

Grade 5 titanium is an aerospace-grade alloy costing around $50–$100 per kg, more than ten times the price of aerospace aluminum 7075 ($5–$8 per kg). Even before machining, the material itself is a major cost driver.

-

CNC machining is a subtractive process. For titanium parts, as much as 90% of the original billet can end up as chips . This means every finished axle or mount represents a far higher raw material cost than conventional materials.

-

With hardness around 36 HRC and poor thermal conductivity, titanium is notoriously difficult to cut. Specialized coated carbide or diamond tools are required, which cost about 3× more than tools for aluminum. Even then, tool life is short — often only 200 minutes of cutting, compared to up to 1000 minutes when machining aluminum.

-

To prevent heat build-up and vibration, cutting parameters must be conservative. While aluminum can be machined at 8000 RPM spindle speed and 0.3 mm/tooth feed, titanium is typically limited to below 1500 RPM and 0.1 mm/tooth . That’s roughly 1/5 the cutting speed and 1/3 the feed rate, meaning each part takes many times longer to produce.

-

Titanium generates high cutting heat and tends to cause tool chatter due to its lower modulus of elasticity. Achieving our required tolerances demands high-rigidity machines, advanced coolant systems, and meticulous process control. These requirements further raise production complexity and cost.

Even with costs this high, we refuse to compromise. Our decision to use premium titanium and labor-intensive CNC machining reflects our respect for every rider who trusts us with their safety. Every gram of titanium we cut is an investment in your ride — a tribute to cycling passion, and a promise that our parts will stand by you wherever the road leads.

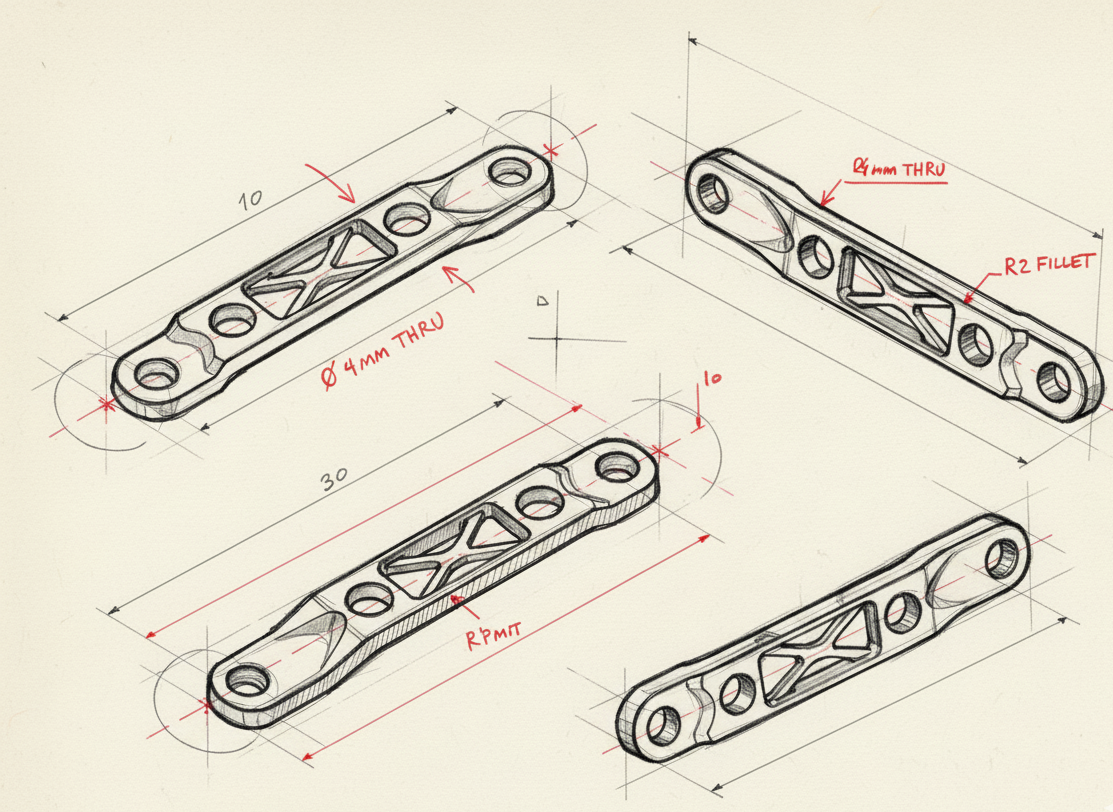

CNC titanium Art

Discover the CNC titanium bike components — enjoy everyday ride with less weight and less concerns.